Separation and filtration play an important role in chemical industry, agriculture and environmental engineering. In these fields a lot of different requirements for every single separation process are obtained depending on the states of aggregation (i.e. liquid-liquid, solid-liquid, solid-gaseous) of the phases. Therefore, the IMVT is working in close cooperation with various industrial partners to find the adequate separation concept for each application.

Research Projects

Particulate matter pollution by soot particles is currently a much discussed topic both politically and socially. The aim of the project described here is to reduce these and thereby improve air quality, particularly in conurbations.

The cleaning of fine solid particles from the air is used in many areas. Therefore, there is great interest in better understanding these filtration processes in order to subsequently optimize them and improve separation performance. In addition, costs can be saved through more efficient energy utilisation.

In internal combustion engines, the use of lubricating oil produces so-called "blow-by gases". In order to prevent them from entering the combustion chamber, they must be separated. The aim of the project is to optimise these separators in terms of energy efficiency, separation performance and installation space.

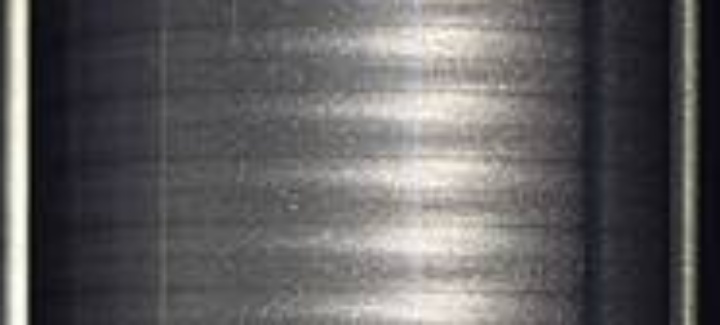

The filtration of highly viscous Newtonian and non-Newtonian fluids is an essential process step in numerous processes in the plastics, chemical and food industries. Therefore, this project deals with the investigation of the use of metallic wire cloth in this area.

In order to better understand the function of depth filter media, numerical simulation is used to investigate the flow through and separation depending on the medium geometry.

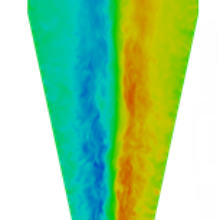

Up to now, the design of aero- and hydrocyclones has mostly been based on (semi-) empirical model equations to determine the most important operating parameters. With the help of numerical fluid mechanics a generally valid design tool is to be created, with whose help any gas and hydrocyclones can be examined.

In the flow processes of disperse and non-disperse systems, hydrodynamic instabilities occur in addition to the known laminar and turbulent flow forms. These are counter-rotating vortices whose axes lie in the direction of the basic flow. This phenomenon is of fundamental interest for the technology, as it usually initiates the laminar-turbulent envelope.

The hydrodynamic instabilities are the subject of experimental and theoretical work to obtain general statements on stability criteria in phase separation processes with moving current field limitations. Their knowledge opens up new perspectives in apparatus design to ensure high separation, clarification, concentration, extraction and classification efficiency.

Modelling and Calculation of Separation Processes of Two-Phase Substance Mixtures in Disk Separators

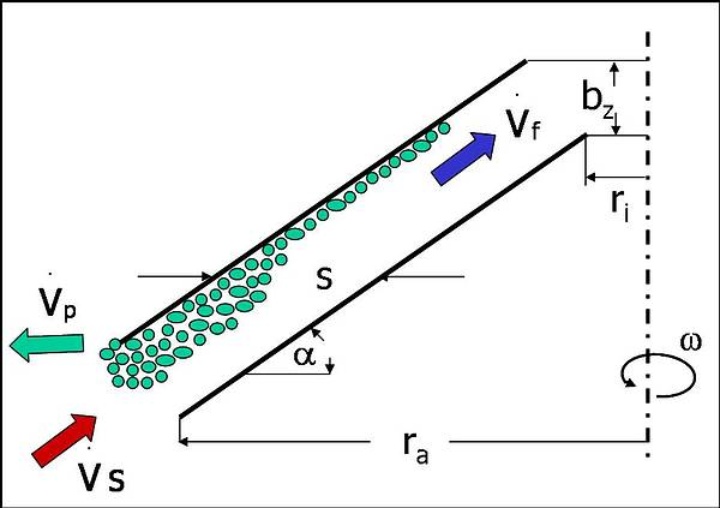

Studies carried out so far on disk separators assume a low concentration of the dispersed phase. Therefore, the question of how the separation behaviour and the pressure drop change with significantly increased solids concentrations remains unanswered so far. In the current research project, this question is to be investigated and insights gained into when a critical concentration of the dispersed phase occurs depending on various geometrical parameters.

In order to be able to make general statements about the relationships between geometry, separation efficiency and pressure drop, both an individual gap analysis is carried out and the entire disk separator is examined. The investigations are carried out with the aid of CFD. Accompanying experiments provide additional findings and serve to validate the numerical simulation results. The separated solids can no longer be ignored in the numerical model, but must be included as a second phase in the considerations.

In order to be successful in the increasingly fierce competition in filtration technology, sound evaluation methods and measurement procedures are required in order to be able to compare filter media. One focus of the work is the determination of the filter medium fineness and the pressure loss of metal wire cloths of various weave types.

Air classifiers are used to separate dusty components, husks and straw components from the grain harvest. In this project, a new cleaning system for grain with a throughput range of 20 - 150 t/h is to be developed which is improved with regard to the fluidic behavior.

Jakub Wieremiejczuk

M.Sc.Scientific Employee

Gunnar Dwars

M. Sc.Scientific Employee